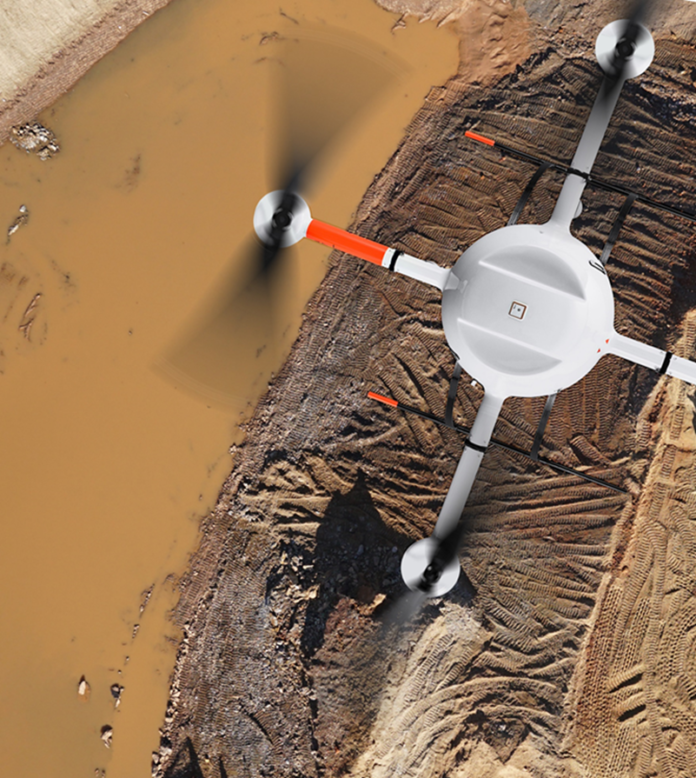

With the rise of drone manufacturing, mining companies are gradually turning to drones to help them improve operations and streamline site operations in a better and safe way. Drones are being used in mining to capture raw visual data. The data can then be converted into several different outputs, such as detailed photos, videos, 3D maps, and orthomosaics. However, one of the biggest benefits drones provide to mining industry is improved safety.

Improving safety in mining sector

Companies aren’t only looking for new ways to improve the safety around their own employees, but also leveraging the latest technologies to help improve their equipment safety in high-risk areas. Drones are one of the few tools that can perform multiple jobs at the same time. For instance, drones can be deployed to quickly assess a mine and identify any existing or potential hazards in remote areas.

Drones can also eliminate the need for helicopters to monitor the area before workers begin service. Project managers are now able to evaluate the project’s needs in advance before organizing the necessary equipment.

Hanno Further says that, as human workers are now being trained to operate drones from a safe location, rather than enter mines themselves to conduct resource estimates, which leads to survey operations becoming significantly safer.

“Using drones eliminates employees’ exposure to potential dangers, especially when compared to the old conventional survey methods,” he concludes.

Staffs are no longer at risk, as nearly everything can be overseen by a drone and the information can be reported back to management, where they will be able to make further decisions without staff having to get involved and perform these tasks themselves.

“Drones are widely used to decrease the risk of people getting harmed. Geodesists, mineral surveyors and other specialist have no need to be physically present at survey sites, which can be dangerous. Also, the same amount of work can be done faster and more effectively, saving manpower for other tasks. Demolition works can be controlled remotely as well,” comments Ilya Demko of Geoscan.

“Drones are widely used to decrease the risk of people getting harmed. Geodesists, mineral surveyors and other specialist have no need to be physically present at survey sites, which can be dangerous. Also, the same amount of work can be done faster and more effectively, saving manpower for other tasks. Demolition works can be controlled remotely as well,” comments Ilya Demko of Geoscan.

With reference to Amit Thokal of ideaforge , drone-led surveying, mapping, surveillance and inspections can help improve the overall safety standards within and around the mining site. Drone-led surveying is about 80% faster and cheaper than manual surveying. Also, the spatiotemporal accuracy of drone-led surveys and maps is a good 80% better than manual surveys.

This means that the surveyors can spot errors/anomalies faster and better using drones. Anything from hotspots across coal stockpiles or faults in key machinery can be quickly spotted with the drone’s high-resolution visual and thermal imaging. These errors can be corrected before they turn into bottlenecks or disasters.

“Drone-led surveying is helpful with blast planning. This helps safeguard many human lives. Similarly, the drones help with tailing dam planning, haul road planning, safe volumetric estimations, and asset inspections. The drones also ensure secure the perimeter with automated and frequent surveillance,” says Amit.

“Drone-led surveying is helpful with blast planning. This helps safeguard many human lives. Similarly, the drones help with tailing dam planning, haul road planning, safe volumetric estimations, and asset inspections. The drones also ensure secure the perimeter with automated and frequent surveillance,” says Amit.

Additionally, Terence Thiel, Channel Sales Manager EMEA at Wingtra points out areas in mining sector where drones play a major safety role.

Haul Roads:

Haul roads must meet certain requirements, including height, or mine owners face regulatory fines. As a mine’s shape can typically change anytime from a couple of weeks to three to six months, so crews must constantly build new ways into the pit and move stockpiles, meaning haul roads need to be adjusted and optimized to make sure that they are not only efficient but safer as well. A lot of the sites operating in the region face heavy rains as well and therefore need to have updated analysis and overview of the roads as well, meaning the drones allow you to do this on demand.

Drones help create a digital twin of the site for the mining engineers to use for future development and planning as well as ensuring that the current state of the site meets regulatory standards.

Blasting:

Blasting:

Drone data also can create 2D and 3D models of the mine before and after blasting. Currently, without a drone, there’s no way for surveyors to go onto the side of a pit’s walls for an accurate reading of their height and angle. Any shift on a wall indicates it’s more likely to fail than others, a huge safety risk.

Stockpiles/Berm Walls:

This is also a key aspect where drones help monitor and create plans for the mine expansion on the walls and stockpiles of the pits. For example, with Stockpiles, you would currently need to stop operations or fit them into an active site in order to get accurate data. Berm walls are always changing and due to the current technology, it’s very reliant on the experience of the surveyor to recognize these things without having the more extensive data to back it up. The Berm Walls can now be monitored on an on-demand basis as well and the teams can focus on areas of concern. This empowers teams on the ground to make up to date and informed decisions.

Lastly, as the push continues for mines to become more environmentally friendly and as drones consistently prove their value, adoption will increase. That’s already happening in places like Africa where regulations are laxer, with Thiel estimating that 95 percent of sites there already have a drone, whether fixed-wing or quadcopter and probably half of them have two.

Mining optimization using drones

Mining is one of the most essential industries across Africa. Proper drone-led optimization could see a bump of about 3-5% in productivity or more. Drones help optimize everything in mining, right from the initial block surveying and planning. Authorities can make accurate estimations of the expected output through drone-enabled 3D Digital Elevation Models, Contour Profiles, Soil-Analysis, etc. They can plan for future construction of facilities, stockyards and haul-roads. All this, when done with precision, can save millions in the long run, this is according to Amit Thokal.

“During the mining, efficient operations management using drones can help quick volumetric estimations, better loading-unloading tracking, and thorough asset inspections (with better maintenance). Furthermore, all survey, mapping and inspections can be done remotely. The engineers and management can view secure live feedback from the on-site drones. This helps with quick and learned decision making,” Says Amit.

“Overall, the main advice for mining optimization is to look at all the operations as a whole. Something as minute as a 1% increase in the rolling resistance of the haul roads can reduce the speed of the trucks by 18-26%. This impacts the haulage costs and production turnover. Drones would help check and contain all these contingencies. These small drone-enabled benefits would add-up eventually for higher output and smoother operations,” he adds.

In Ilya’s opinion, the use of drones is already what helps optimize and improve mining. Training people is what can really help. New technologies appear rapidly and personnel needs to be trained. The lack of educated people who can operate drones as well as specialized automatic services, hampers companies implement drones in their work.

However, on the other hand, Terence Thiel believes that, the main points to focus on are the; ease of use, reliability and durability, accuracy, and how it integrates into the current workflow. “If you keep those points in mind when deciding to go with Drones you will ensure that you are aware of your capabilities, the insights that you will gain, and empower the teams on the ground,” he insists.

“From exploration, surveying and mapping to maintaining safety and enhancing security, mining companies are coming up with many new ways of using drones within the industry,” states Hanno. “The unlimited aerial data that can be collected with drone technology means engineers can record and track more information in less time, allowing them to focus on analysis and interpretation,” he adds.

In his perspective, Hanno talks of five key trends for drones in mining –

1. Monitoring and inspection

Mining is among the most dangerous industries for workers, especially those working deep underground. Workers can be subjected to hazards such as rock falls, humid conditions, gas leaks, dust explosions, and floods.

Addressing this, mining companies have used drones in such mines to monitor and inspect deep shafts. Drones are also being employed to inspect mining equipment, which is an expensive and time-consuming process requiring a highly-skilled workforce.

2. Automatic surveying and mapping

Surveying and mapping of mineral landscapes is typically a time-consuming process. By employing drones and a drone pilot, instead of a piloted plane, a mine can save around 90% of the cost-per-hour and collect unlimited aerial data. This includes fine measurements by simultaneously capturing high-end ortho-images.

3. Stockpile management

One of the biggest challenges any mining company faces while managing stockpiles is the extreme height and area covered, which tends to change frequently. Drones can enable mining companies to generate aerial terrain models of their inventory and ensure companies can effectively keep track of stockpile movement.

4. Haulage road optimization

The haul road network has a significant impact on the efficiency of mining activities. To achieve safe and uniform transit, road conditions must be constantly monitored. Drones can facilitate this process by collecting a large amount of aerial data, covering wider areas more precisely, which can then be used by engineers for planning, designing, construction and maintenance activities.

5. Tailings dam management

The use of drones to measure tailings dams could eliminate the risk of manual surveying. There is no need for manual interference within the proximity of the dump when drones are available. By analysing the captured data on a digital platform, mining companies can maintain the structural integrity of the tailings dam to help prevent failure.

Mining is one area where the use of drones is increasingly being establishing as an integral part of the overall operations. Today, Mining sites in Africa are portraying substantial penetration of drones in supporting their mining applications increase operational efficiency and develop new services and business models, from exploration, surveying and mapping to maintaining safety and enhancing security. Hence, making the mine sites more efficient, profitable and safer for employees, contractors and visitors. Undoubtedly, drones can significantly improve the operational efficiency of mines through improving commodity resourcing and replacing outdated and time-consuming processes.